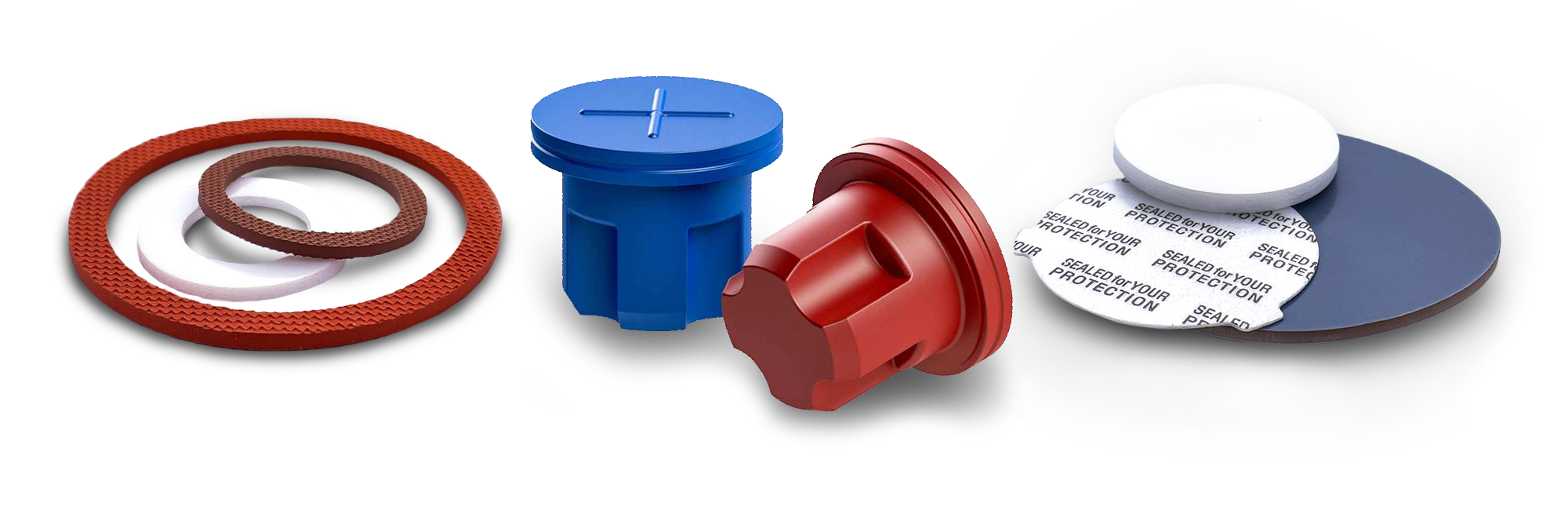

Liners, rings and gaskets

CapLiner

As packaging specialists, we supply you with the right sealing discs, sealing inserts and septa for every application and every filling material. As part of KISICO’s services, we offer advice on the selection of the optimum seal for the respective application. In doing so, we look for the most economical way to ensure safety and reliability.

Depending on the application, seals supplied by KISICO have approvals in accordance with USP, EP, FDA, BfR or a Drug Master File regulations. Be it injection-molded polyethylene gaskets, injection-molded TPE gaskets, PTFE laminated gaskets, foamed gaskets, induction sealing foils or gaskets made from varying qualities of rubber – our experts will find a suitable gasket for every need. We take responsibility for the perfect fit of the sealing discs in the KISICO closures.

We promise to find an adequate sealing solution even for problematic filling goods such as aggressive chemicals, volatile substances or silicone oil.

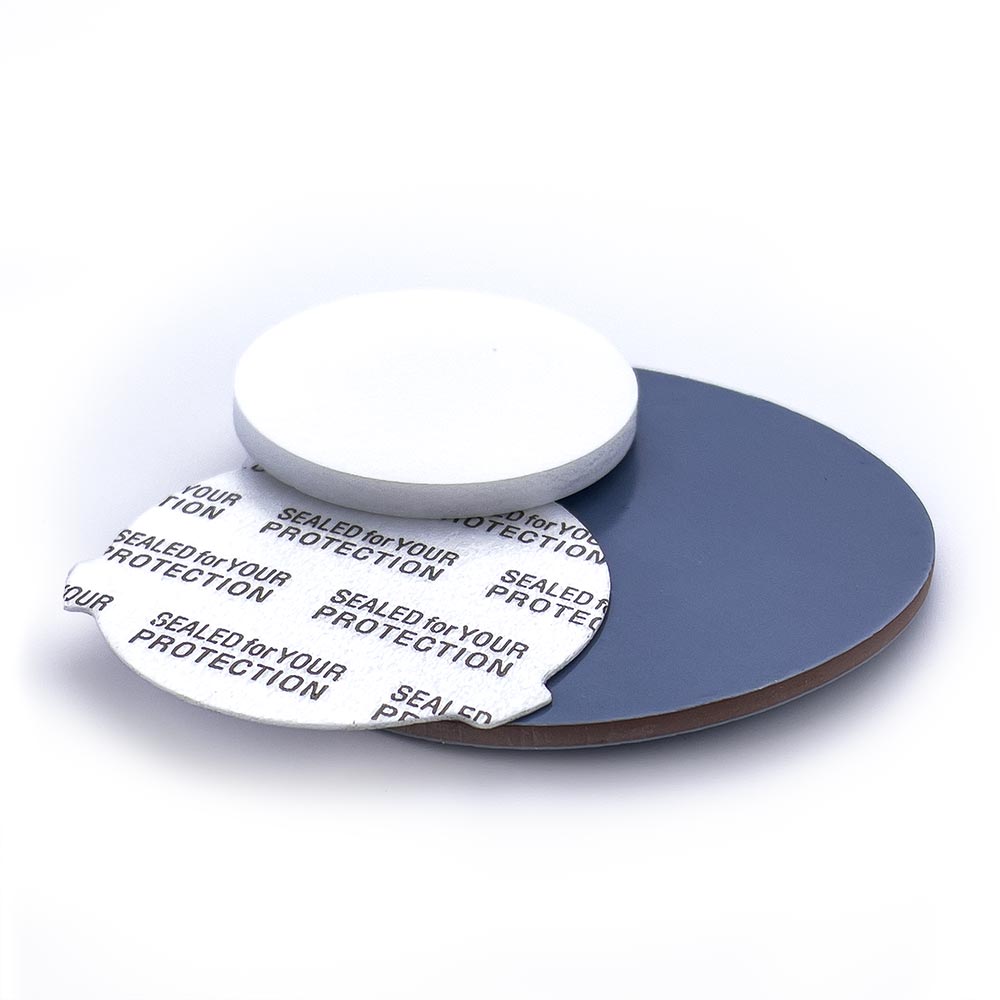

Liners, gaskets, rings

Liners and gaskets made from foamed PE, rubber, TPE and many other materials. Available in in a variety of diameters and thickness.

Pierceable septa

Pierceable septa with customizable features such as design, hardness grade, temperature-resistance, and color.

Stoppers for lyophilization

KISICO’s TPE stopper is a pioneering solution that is the future of freeze-drying stoppers. An alternative to traditional rubber stoppers, TPE is latex-free and requires no additives, crosslinking agents or reaction promoters, all of which could have a negative impact on the product they come into contact with.

Our advanced injection molding technology ensures cost efficiency and the highest quality standards. Production in a cleanroom facility ensures maximum product purity and eliminates the need for post-production washing processes. Camera-assisted inline quality control verifies compliance with product specifications for each individual stopper.

Only medically-approved raw materials that have been tested for biocompatibility are used to manufacture stoppers. They comply with USP Class VI. These materials have excellent sterilization properties for gamma irradiation and autoclaving or ethylene-oxide sterilization. Materials and colorants can be customized to meet customer needs. All TPE stoppers are recyclable and more sustainable than stoppers made from other materials due to reduced production waste.

Find your product

Tags

KISICO

Kirchner, Simon & Co. GmbH

Rieslingstrasse 41

65375 Oestrich-Winkel

Germany

Phone: +49 67 23 99 65-0

E-Mail: info@kisico.de

As cap & closure experts, we have been providing optimal safety for your products and to your consumers for over 75 years. Our expertise and competence offer you a competitive advantage through customized and innovative solutions.