Caps with special capabilities

XtraCaps

Our experienced team of engineers and technicians is constantly on the lookout for novel solutions that can be applied to the production of our caps. The XtraCap range includes some of the most innovative caps in our assortment.

KISICO is always playing to its strength in innovation – our HologramCap offers optimal counterfeit protection, the NFCCap has won accolades from the World Packaging Organization and the ReservoirCap enables the mixing of various contents.

We are also always looking for ingenious ways to improve our existing closures and putting them into practice.

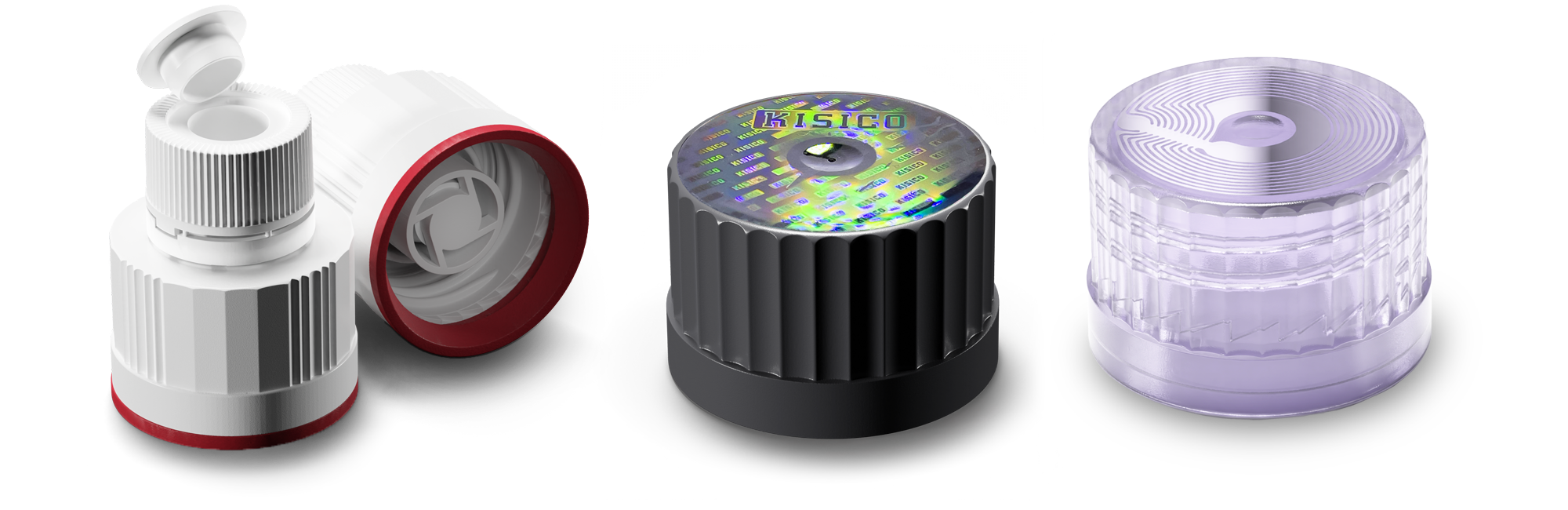

Caps with integrated NFC tag

Our revolutionary NFCCap enables contactless communication with any NFC-enabled smartphone. For phones without an NFC reader there are corresponding add-on devices.

This technology can be built into most closures from KISICO’s standard range. This avoids the costs for new injection molds or mold modification. The closures retain their design because the chip is not visible from the outside. One advantage for users in the food, chemical and pharmaceutical industries, is that the chip does not come into contact with the filling material.

A wide range of information and commands can be programmed onto the chip. Appropriate applications can be used to verify that the product is not a counterfeit. This technology can also be used to communicate with a tech-savvy target group. Links to websites, product data sheets or specially developed apps can be opened by communication between the closure and smartphone.

Caps with dosing chamber

Demand for dosing caps is on the upswing and KISICO´s ReservoirCap is the optimal solution for those needs. These caps allow substances to be mixed immediately before use.

The ReservoirCap is supplied with a ready-to-fill container. The ingredient is simply poured into the reservoir at the top of the cap. After this simple filling process has been completed, the container is closed with a lid. The ingredient is now completely enclosed in the cavity and protected from all external influences. No other sealing equipment is required. The lid is then screwed onto a standard bottle with a PP28 mouth. This bottle can be filled with a liquid. If required, the reservoir can also be filled after the ReservoirCap has been screwed onto a bottle filled with liquid. Turning the smaller cap opens the container and the substance from the reservoir falls into the bottle.

The closures can be produced in cleanroom facilities and from pharmaceutical or food-grade materials.

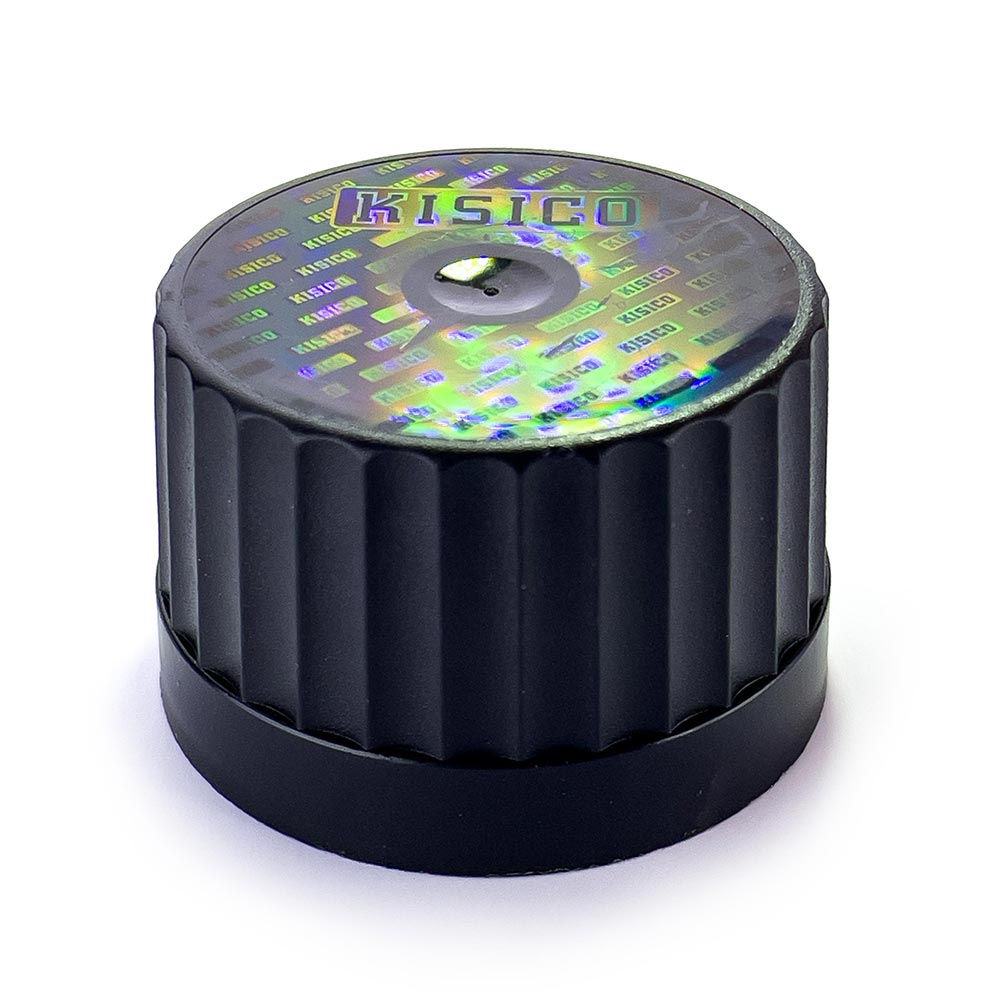

Caps with holograms

KISICO´s HologramCap is a trendsetting innovation. Get our existing and popular closures with an additional counterfeit security feature.

Unique breakthroughs in nanotechnology enable KISICO to offer customers unrivalled protection against counterfeiting. The design features a hologram that is fully integrated into the production process of the cap, thus requiring no additives, inks, or labels. The style of the hologram can be customized according to customer needs.

In combination with the tamper-evident ring, the HologramCap offers the most advanced protection to consumers and brand owners on the market. This solution is not only interesting for the pharmaceutical industry and others who package high-grade products. The attractive and unique appearance can also be used to differentiate between products and emphasize their high quality.

Find your product

Tags

KISICO

Kirchner, Simon & Co. GmbH

Rieslingstrasse 41

65375 Oestrich-Winkel

Germany

Phone: +49 67 23 99 65-0

E-Mail: info@kisico.de

As cap & closure experts, we have been providing optimal safety for your products and to your consumers for over 75 years. Our expertise and competence offer you a competitive advantage through customized and innovative solutions.